Most craft breweries are proud of how they minimize the environmental impact of their practices and processes, but regardless of how many solar panels a brewery has on the roof, there is one byproduct that cannot be avoided but is often ignored: Carbon dioxide, a byproduct of fermentation. Hoses run into buckets of water and bubble away releasing CO2 into the atmosphere. According to the EPA, CO2 is the primary greenhouse gas emitted through human activities. Beer is a human activity.

I want to save the world as much as the next guy, but I’d also like to keep drinking beer.

A clever start-up venture in Colorado, Superior Ecotech, has figured out a way to mitigate the CO2 released at breweries. They’re asking for your help via a Kickstarter campaign. I won’t go into details, but will encourage you to check out the video below and also go visit their Kickstarter page. TODAY is the last day of their campaign and they are close to reaching their goal.

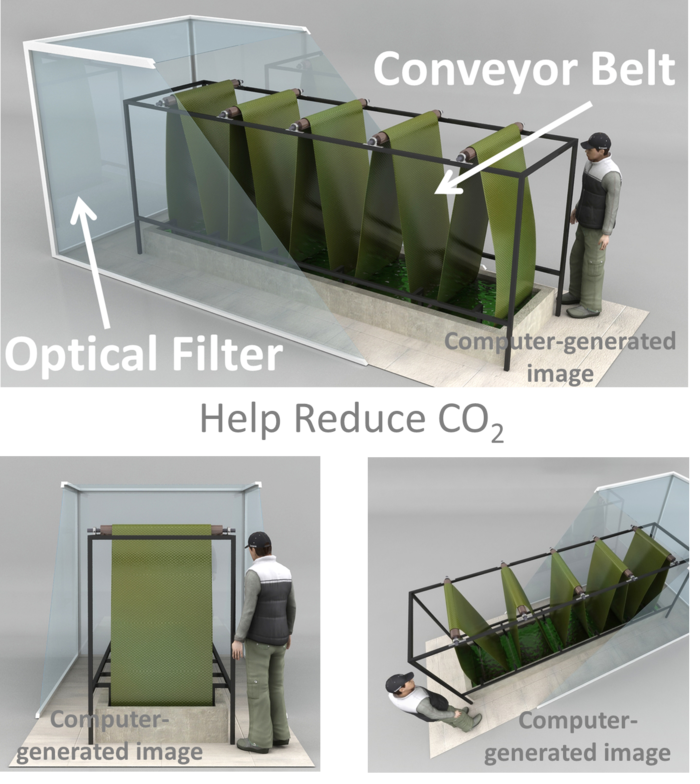

The short version: CO2 is pumped into a specially designed algae greenhouse on the roof of the brewery. Algae soak up CO2. Algae “inhales” CO2 and convert it to useful oils. In the end, instead of producing beer and CO2, the brewery would be producing beer and useful, sustainable, vegan-friendly, omega-3 oils. The Kickstarter campaign will fund a greenhouse built on the roof of Upslope Brewing in Colorado to prove the concept.

There are a lot of beer-related Kickstarter campaigns these days. This project is as much about sustainability as it is beer. This is not simply about helping one group of people start a brewery or introduce a new kind of growler. This is different. That’s why I decided that this Kickstarter campaign was worth sharing.

I’m pretty sure the CO2 emitted during fermentation is neutral. The barley that the sugars came from, which has the CO2 released was not buried in the ground. That barley soaked up that CO2 (with water and sunlight) to make oxygen and use the carbon. We are only releasing CO2 that is part of the active environment. Fossil fuels are not part of the current environment and are the problem.

I would like to see the calcs on this for how much fossil fuels get used to build and or ship this product to see if the total life-cycle cost is a net positive or negative.

I’m not a scientist but I’m pretty sure I have this right.

A simpler solution would be to just plant a lot of trees with the money going into this.

My 2 cents anyway.

We’ll do our part in getting the word out via social media about this Kickstarter campaign of the Colorado start up.

Unlike the guys behind this idea, I’m not any kind of chemist or scientist. If all they’re doing is creating a way for a brewery to use a byproduct to create a sellable, useable product, it’s still a win in my book.

Is the other kind of gas that beer produces also neutral?

Don – I don’t think it’s carbon neutral. It take a lot of fuel to cultivate, malt, package, and transport the barley.

Righto. The barley might be, but it has to be malted, roasted, shipped, mashed, boiled, etc…

But I did see this today: http://cycleco2.com/ Frankly, I’d rather reuse the co2 we produce to carbonate and push our beers than get into a secondary oil market.